Flooring Update 2018

Underlayments

We installed a ton of underlayments. There was a 1/8" rubber soundproofing layer. There was a 0.01" thick aluminum foil radiant barrier. There was 1/4" luan plywood layer. There was a CMP self leveling underlayment. There was also a key resin flexible epoxy membrane applied ontop of all that.

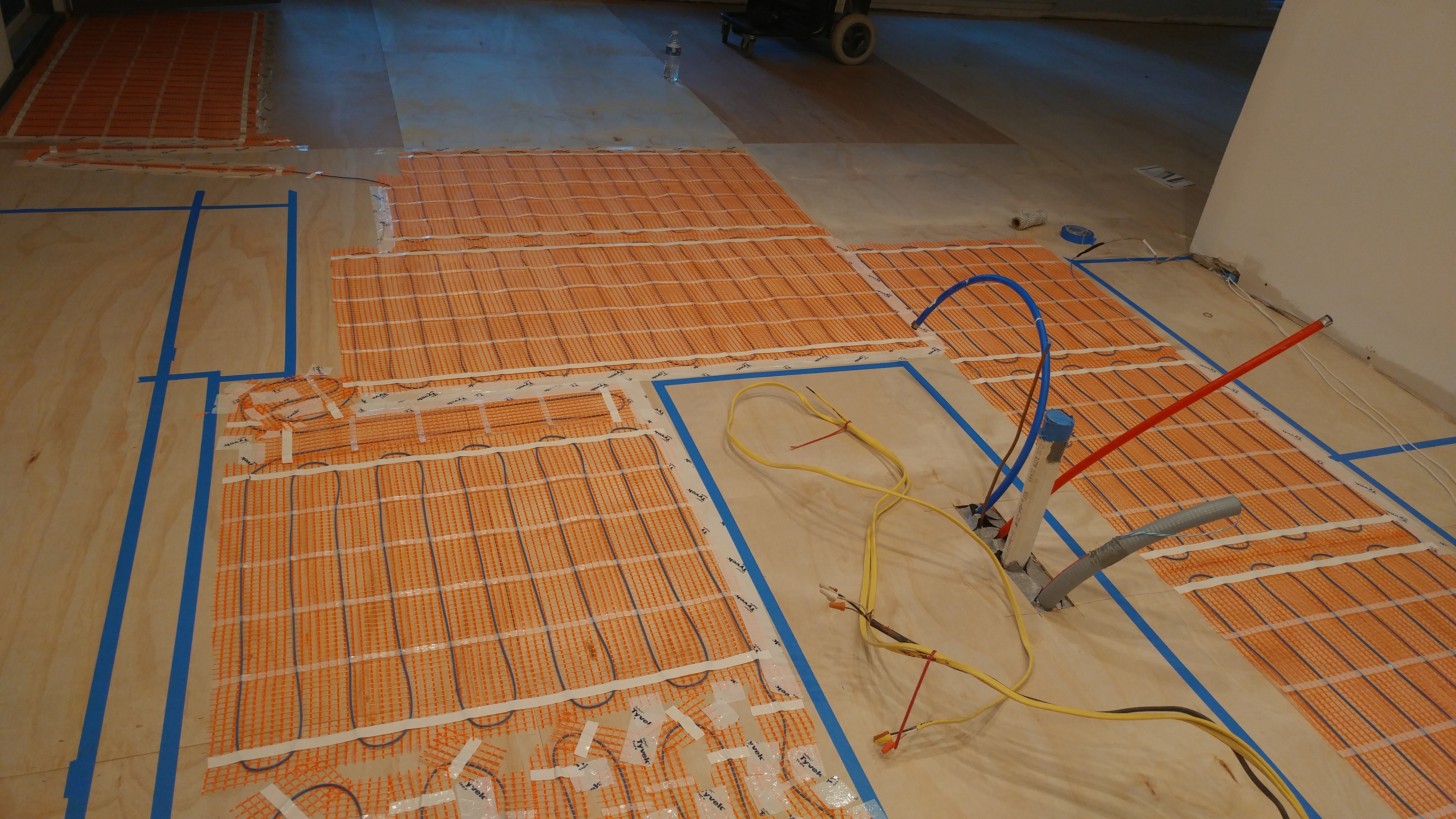

Electric Floor Heat

We installed 140sq ft. of electric flooring in the kitchen and over the annex (which used to get numbingly cold in the winter). We had to use a small 1/4" or 1/2" transition with the cmp self leveler because of the extra thickness required by the heating but it will really help keep the house comfortable in the winter.

Epoxy

We had specific requirements for the epoxy look and we had to re-pour the epoxy once because the mixture ratios were off the first time around. This means our floor is an extra couple mils thicker and stronger than it would have been in a perfect install. First there is a base coat that is light grey. Then a darker grey metallic coat is applied overtop, which ends up more and less opaque in different places, and settles into the epoxy at different depths, creating a complex and interesting color and texture. There is a satin / matte topcoat applied which removes the glossy / shiny look and really makes the finished product look pretty darn close to an acid washed / polisihed concrete.